选择语言

选择语言

RAW MATERIAL SELECTION

SMALL THINGS MATTER

Only the most reliable and prominent components after rigorous quality control experiments are selected for the inverters. 90% of them comes from World Top 500 companies because we know small things matter.

Incoming Inspection

All the incoming raw materials will be sample inspected by certain proportion based onISO9001.

Failed components will be rejected together with the batch where they belong to.

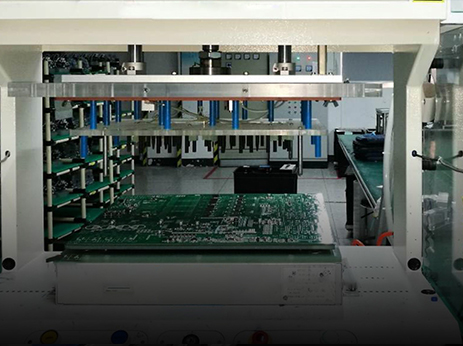

ICT Test

In-Circuit Test ensures that each piece of PCBA board is of perfect working conditions

ISO Test

ISO functionality Test is designed for insulation, electricity leakage, safety regulations for various countries, grid-tie simulation, safety guaranteed.

Aging Test

Test under 50℃ with high humidity sealed room to simulate extreme environment for 6 hours which ensure seach inverter will maintain its maximum performance without degradation.

ATS Test

All the inverters will be tested through AC&DC Power sources to simulate different weather radiation, load and grid condition for various countries to examine MPPT efficiency and output.

Final Test

Before packaging every inverter will go through a final test for performance record and identification.

ISO QUALITY CERTIFICATES

We are continuously striving to improve the quality of our management systems that enables GoodWe to produce

safe and defect free products and to ensure that delivery and performance of the product will be of customers satisfaction

Certificate

Certificate

Certificate

QUALITY FOR SUCCESS

.png)